Full Automatic Liquid Filling Machine

Horizontal Type Nozzle Liquid Filling Machine

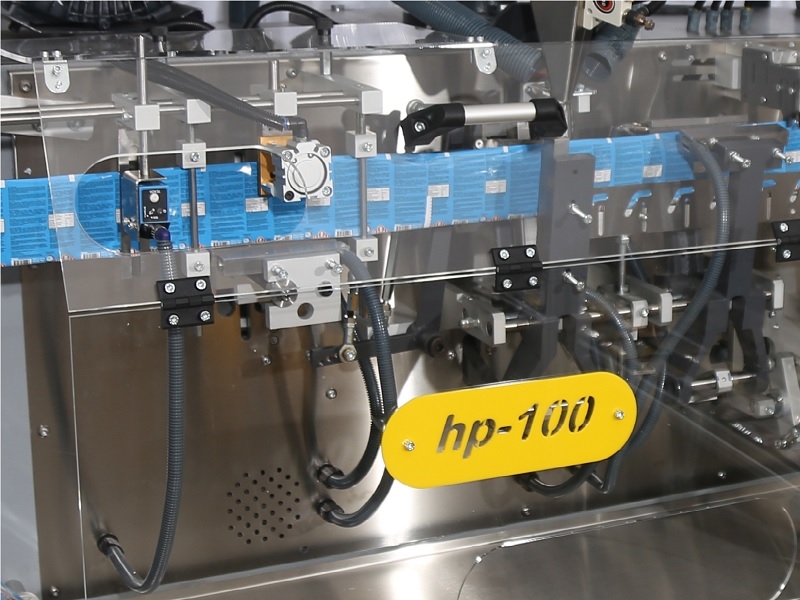

Hp100L / Full Automatik Nozzle Liquid Filling Packaging Machine

Aypamak Horizontal Liquid Filling Packaging Machines are known for their consistency, simplicity, competitiveness and quality. It is easy to use, economical to maintain and reliable. The automatic horizontal liquid filling packaging machines produced by our company have adopted international technology. It can pack your products in various sizes with the synthesis of stable design, efficient and stable operation. It is equipped with a parametric intelligent PLC processing unit. It can perform automatic liquid filling, sealing and packaging. Aypamak HP-100 liquid packaging series is the most optimum choice for performing economical and cost-free packaging.

Horizontal Type Liquid filling and packaging machine is a single line filling and packaging machine designed for horizontal packaging of liquid products between 1 ml and 60 ml. Fully automatic horizontal packaging machine fills liquid products in sachet package type. No Collar form is required. It first unloads the laminated, printed, rolled foil according to the packaging speed of the machine. During the pulling by an automatic servo motor system, the foil is folded in half. In the next drawing pitch, it performs sub-welding, unpacking, vertical welding and cutting operations in pitch order during drawing. It is pulled mechanically to the desired length by means of servo motor pulling system. When it comes to the filling pitch during drawing, the liquid weighed into each package is thrown into the product by a volumetric filling pump through the nozzle.

.

|

Model

|

Hp-100-L

|

| Function |

Fully Automatic Liquid Filling and Horizontal Packing Machine

|

|

Packet Type

|

It is suitable for 3-sided or 4-sided Sachet bag gluing options.

|

|

Volumetric Liquid Filling Pump System

|

|

|

Machine Body

|

Profile material Static Oven Paint, Food Grade, Corrosion Resistant

|

|

Machine Weight

|

350 kg.

|

|

Machine Dimensions

|

230x90x200cm.

|

|

Electric Need

|

3 kw. trifaze Electric

|

|

Air Pressure

|

6-8 bar.

|

|

Open the Foil and Witdh

|

Automatic Foil Opening Motorized

Min 100mm Max 300mm foil width

|

|

Ambalage Material

|

OPP, PE, Aluminyum, Laminated Coated can be used.

|

|

Package Width

Height |

50mm.-120mm wide range of packages 50mm.-120mm wide range of packagesMinimum 50mm. Maksimum 150mm. package size

|

|

Filling Weight Range

|

Between 1 ml and 60 ml

|

|

Packing Capasity

|

60-30 Pieces per Minute It differs according to its fluidity and weight.

|

|

Packing Product

|

With volumetric liquid filling system, Ketchup, Olive oil, Mayonnaise, Disinfectant, Fruit Extract Syrup, Honey, Jam, Chocolate, Vinegar, Salad Dressings, Sunflower oil, Narekchisi, Lemon Sauce, Sterile Water, Margarine, Molasses, Tahini, Butter, Mustard, Tomato Paste Shampoo, shower gel, medicine, etc. All liquid products used in the agricultural industry

|

|

Packing Material

|

Laminated aluminum, metallized, opp, pe foil coil

|

|

Photosel

|

In the printed material, the machine works according to the speckle system. German-made ZICK speckle sensor is used in the machine. Best quality and best with speckle signal sensitivity and easy speckle identification In the printed material, the machine works according to the speckle system. German-made ZICK speckle sensor is used in the machine. Best quality and best with speckle signal sensitivity and easy speckle identification |

| Pulling System |  Servo Motorized Length Pulling System Servo Motorized Length Pulling System |

| Screen |

7" Touch Delta Operator Panel 7" Touch Delta Operator PanelIt is easily synchronized by the operator according to the correct working processes. The package size and speed settings of the powder packaging machine can be controlled by a PLC program suitable for parametric flexible operation with screen intervention. It is a parametric software suitable for different production processes. |

| PLC & Software | Delta PLC ve Parametric Aypamak HP100L software |

| Main Motor Driver | Schneider |

| Contactor-Fuse | Schneider |

| Relay | Phonix |

|

Welding Rezistans

Termostat-SSR

|

Dc48 volt Rezistans

Enda Termostat

Enda SSR

|

|

Cutting System |

Sequential filled packages are cut and single packages are dropped. The cutting system and blades are made of long-life tool steel against blunting. A special steel material is used for long-lasting use. Hardened and specially processed knives reduce long-term usage costs to zero. Both surfaces of the blades are suitable for use alternately for cutting purposes.

|

| Guarantee |

Mechanic Electronic Guarantee 1 Year

|

| Document |

User Manual

Electric circuit and Wire Shema

|

| Training İnstallation |

Free Training and Installation Service

7/24 Whatsapp Help Support

|

|

Optionel

Systems

|

Date Coding, Feed Pump, Notching, Die Cut, Outlet Conveyor, Screw Filling, Volumetric Granular Filling |

All processes such as software, electricity, automation, service, spare parts, production are done within our company. In the face of problems that may occur in the machines in these matters, our company intervenes without interrupting the production. In these areas, our company does not find it appropriate to work with suppliers. For the continuity of its customers' production processes, our company always offers itself an experienced, knowledgeable and prepared problem solving approach.

It is fast and efficient.

They are systems that do not require a lot of personnel and minimize labor costs.

It ensures efficient use of limited resources.

It plans consumption in accordance with human health.

It provides the opportunity to stock up as much as consumption needs.

It provides fast sales and high profitability in the short term for the business.

They are systems that do not require a lot of personnel and minimize labor costs.

It ensures efficient use of limited resources.

It plans consumption in accordance with human health.

It provides the opportunity to stock up as much as consumption needs.

It provides fast sales and high profitability in the short term for the business.